info@pacificcontrols.com

edm,micro,holes,mitsubishi,charmilles,sodick,agie,deep,beaumont,belmont,current,hycon,supplies,technologies,echo,solutions,zap,

makino,nnoble,ex,resources,solutions,system3r,hirschmann,erowa,sunspot,methods,network,edvanced,intech,technologies,

ENGINEERING

JOURNAL

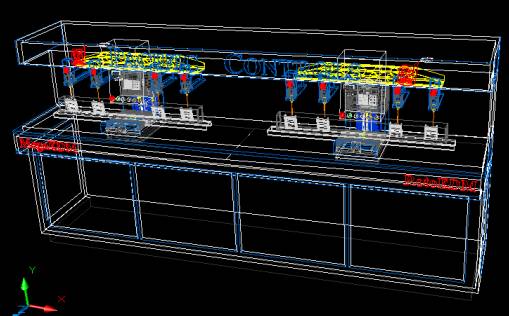

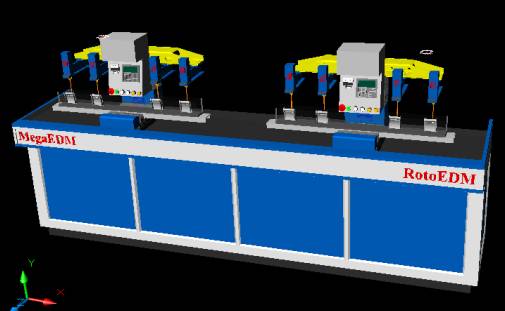

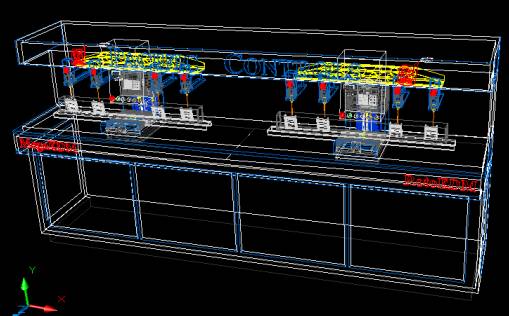

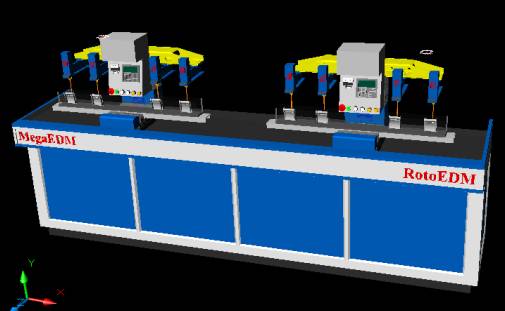

MegaEDMsTM

Unmatched Cost Savings

Best

ROI on today's Market

of

Floor Space

& Labor

& Energy & Maintenance

Demonstrated

4,000%

Production Increase

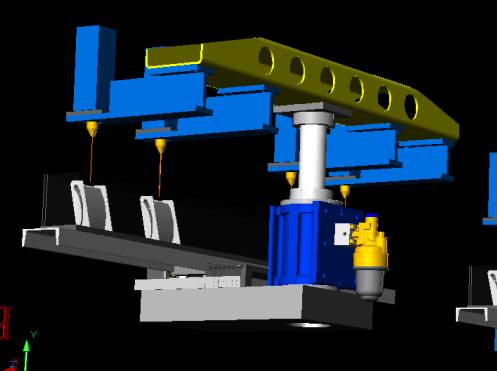

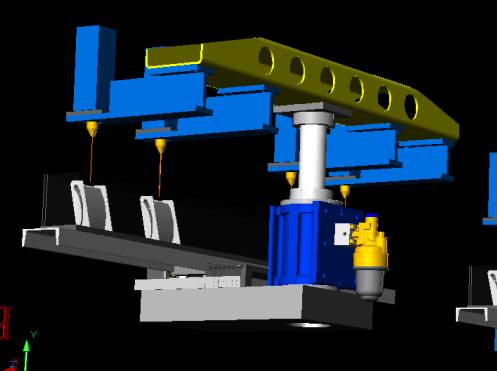

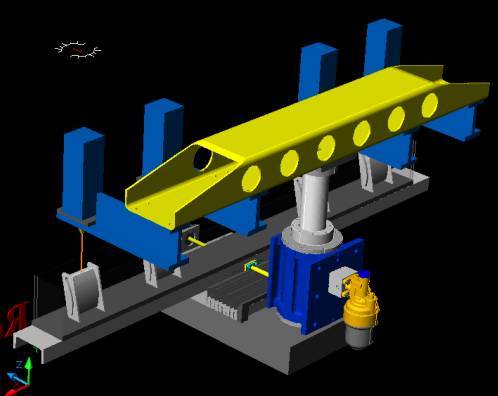

The main feature of Pacific Controls MegaEDMsTM is to

EDM multiple work pieces simultaneously.

Having the expertise in the design and in-house manufacturing ability of

custom tailored

EDM Systems, to package multiple work stations on a single chassis was a easy especially

since Pacific Controls High Response Hydraulic Servo, without losing any of its response, can

be easily

loaded with multiple

Electrode Tooling.

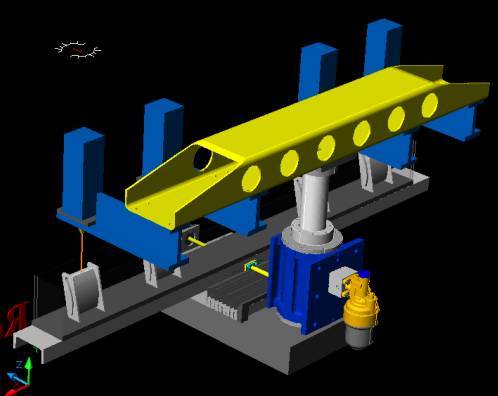

Presently Pacific Controls Company offers three

types of MegaEDMsTM

__________________________________________________________________________

EDM Drilling

up to eight (8) parts simultaneously

__________________________________________________________________________

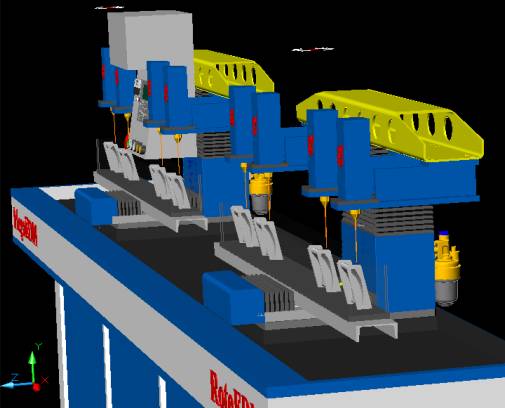

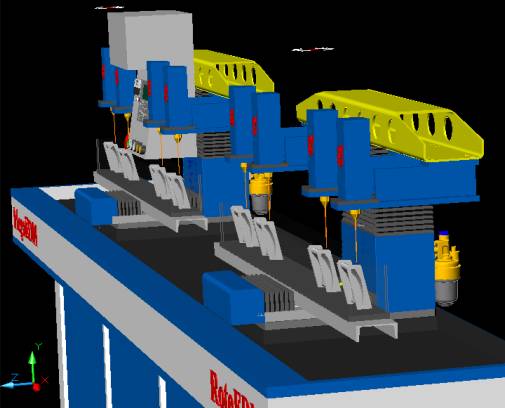

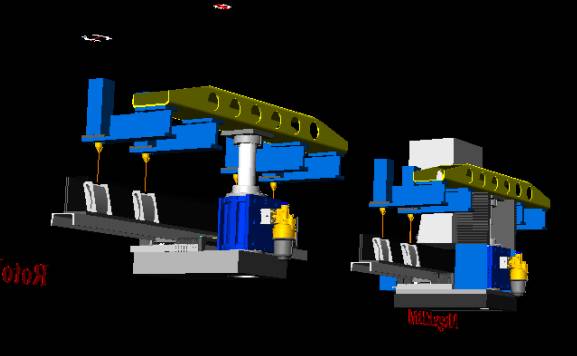

For

more complicated burns, requiring turning of the work piece and EDMing with

multiple electrodes, as required on aerospace fasteners, logical answer is the

__________________________________________________________________________

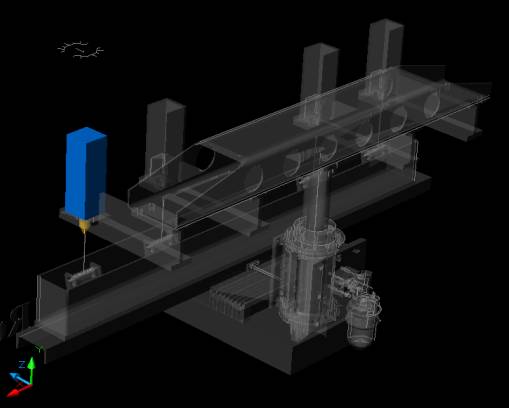

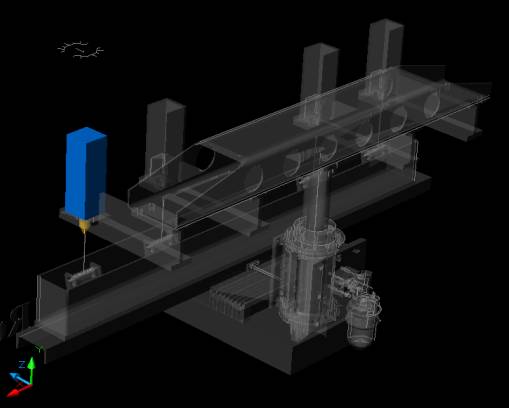

Third MegaEDMTM System offered by Pacific Controls incorporates

High

Speed Micro EDM drilling required in manufacturing of Fuel Injectors.

Injector

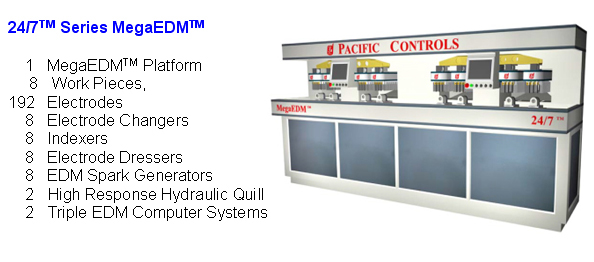

24/7TM

is another simple answer to large problem

__________________________________________________________________________

MegaEDMsTM

thatís

Simplicity, Ingenuity, Savings

RotoEDMTM

__________________________________________________________________________

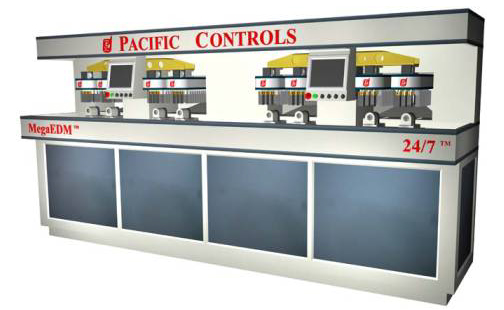

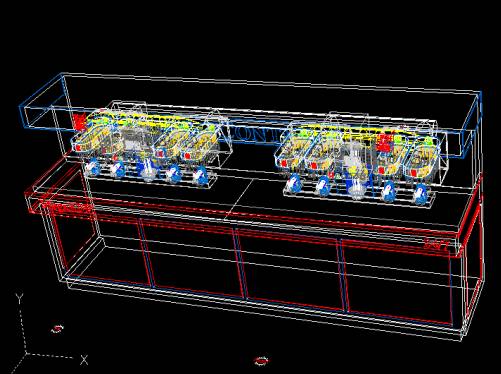

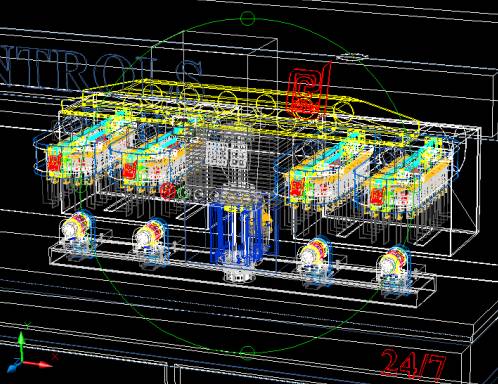

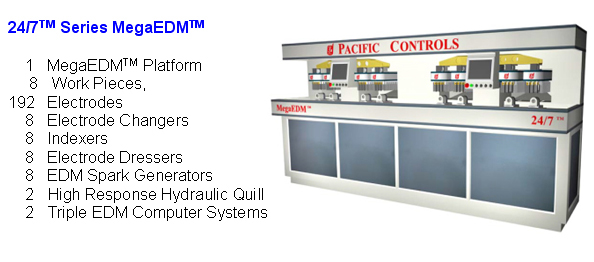

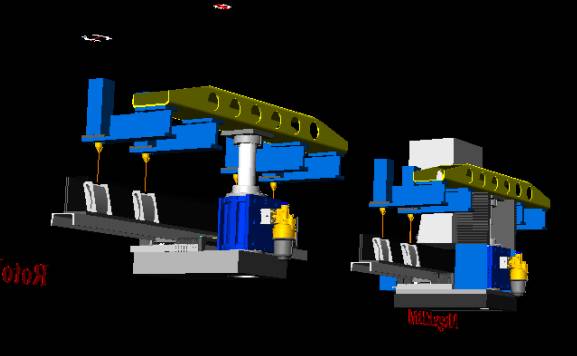

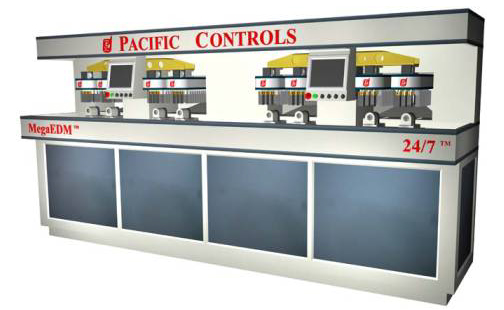

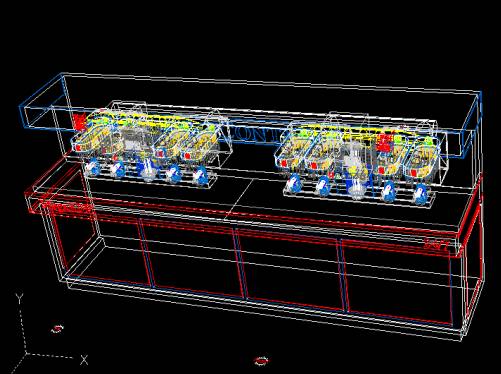

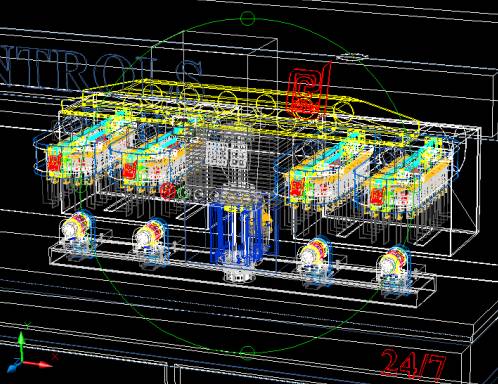

MegaEDMTM 24/7

This model was designed to

demonstrate just a few possibilities Pacific Controls MegaEDMsTM

are

capable of. Combining Electrode Changes,

Indexers and XY Tables, packaged into single

MegaEDMTM platform results into production output no

one dares to match.